Comprehensive Technical Solution for Mercury Abatement

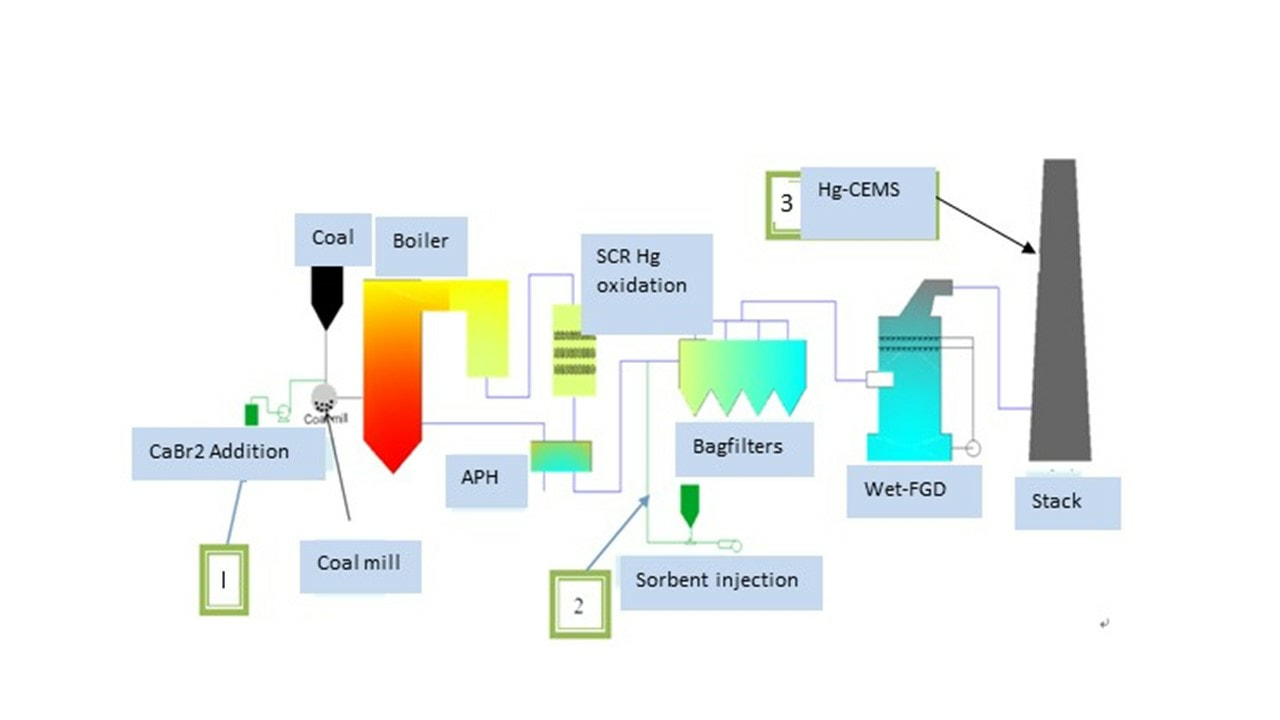

Integrated solution of mercury control, including calcium bromide addition on the coal, injection of brominated activated carbon before the precipitator, mercury online monitoring system at precipitator / FGD / stack, and the controlling system is based on the feedback of total mercury and speciation mercury that measured by the mercury online monitoring system, to control the calcium bromide solution addition and the injection of bromine activated carbon.

Calcium bromide solution addition system is located in the coal feeder platform, by multi independent control loops corresponding to each coal feeder. The added calcium bromide decomposed in the furnace to form HBr and Br2 to oxidize elemental mercury to ionic mercury in flue gas under the SCR catalytic promotion. The amount of CaBr2 solution addition is calculated by the mercury controlling center based on integration of the amount of coal supply, the coal type, the operation conditions of FGD and the mercury speciation measured by Mercury CEMs, etc.

If additional layer enhanced mercury oxidization SCR catalyst installed to promote mercury oxidation in the flue gas, the above calcium bromide solution system will be eliminated. It is best to equip enhanced mercury oxidization SCR catalyst if budget permits.

A sorbent injection system is located at the inlet of the precipitator, using positive pressure conveying (convey pac to 12PSI), weightlessness metering and constant splitter technology, so that the quantitative brominated activated carbon is evenly distributed in the flue gas to capture gas phase mercury in the precipitator, which will have a continuous adsorption effect on the total gaseous mercury. The injection volume of activated carbon is calculated by the mercury control center based on the concentration of total gaseous mercury measured by mercury CEMs and the ratio of calcium bromide solution.

The total Mercury emission is accurately monitored by Hg-CEMS which online measures total mercury and its speciation in a real time, also feedback to the mercury control center. The center accordingly adjusts the amount of calcium bromide and the amount of activated carbon injection to comply emission regulation. Meanwhile, the center also calculates the best combination ratio of calcium bromide solution and bromine activated carbon in order to reduce the operation cost and regulation compliance emission at the same time, to achieve the most economical combination.

Integrated solution of mercury control, including calcium bromide addition on the coal, injection of brominated activated carbon before the precipitator, mercury online monitoring system at precipitator / FGD / stack, and the controlling system is based on the feedback of total mercury and speciation mercury that measured by the mercury online monitoring system, to control the calcium bromide solution addition and the injection of bromine activated carbon.

Calcium bromide solution addition system is located in the coal feeder platform, by multi independent control loops corresponding to each coal feeder. The added calcium bromide decomposed in the furnace to form HBr and Br2 to oxidize elemental mercury to ionic mercury in flue gas under the SCR catalytic promotion. The amount of CaBr2 solution addition is calculated by the mercury controlling center based on integration of the amount of coal supply, the coal type, the operation conditions of FGD and the mercury speciation measured by Mercury CEMs, etc.

If additional layer enhanced mercury oxidization SCR catalyst installed to promote mercury oxidation in the flue gas, the above calcium bromide solution system will be eliminated. It is best to equip enhanced mercury oxidization SCR catalyst if budget permits.

A sorbent injection system is located at the inlet of the precipitator, using positive pressure conveying (convey pac to 12PSI), weightlessness metering and constant splitter technology, so that the quantitative brominated activated carbon is evenly distributed in the flue gas to capture gas phase mercury in the precipitator, which will have a continuous adsorption effect on the total gaseous mercury. The injection volume of activated carbon is calculated by the mercury control center based on the concentration of total gaseous mercury measured by mercury CEMs and the ratio of calcium bromide solution.

The total Mercury emission is accurately monitored by Hg-CEMS which online measures total mercury and its speciation in a real time, also feedback to the mercury control center. The center accordingly adjusts the amount of calcium bromide and the amount of activated carbon injection to comply emission regulation. Meanwhile, the center also calculates the best combination ratio of calcium bromide solution and bromine activated carbon in order to reduce the operation cost and regulation compliance emission at the same time, to achieve the most economical combination.